- 商品详细介绍

|

BR型气体继电器 |

| 油浸式变压器大多数故障总是伴随着气体的产生。 使用合适的气体继电器(BR气体继电器)可作为监控故障的报警装置。 通过分析继电器内积聚的气体可以较好的了解故障的类型,但当变压器处于运行状态时,直接从气体继电器中采集气体的危险性较大。 集气盒(气体采样装置)可以有效规避这种风险性,通过安装在变压器上便于接近的位置,同时远离并连接上气体继电器从而实现气体采集的功能。 |

| 技术特征 |

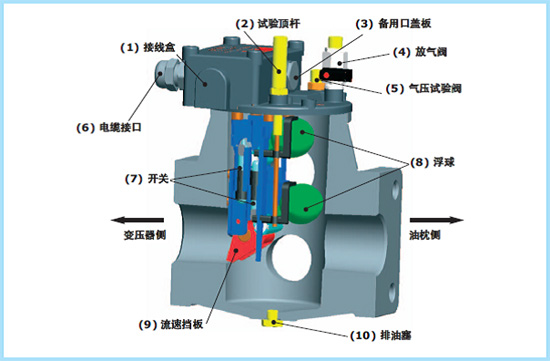

BR型气体继电器由经机械加工处理的两铝合金铸件装配而成且可实现良好的油密封效果。 |

|

|

BUCHHOLZ RELAY “BR” TYPE |

Most faults in oil filled transformer are accompanied by the generation of gas. By using a suitable relay (BR Relay) the formation of this gas can be used as a warning of a developing fault. |

| Technical features |

| The Buchholz relay BR type is an assembly of two machined aluminium alloy castings that effect a perfect oil seal. 1)The main body of the relay is fitted with tempered glass inspection windows with graduated scale markings in cubic centimeters to indicate the internal volume. The oil drain plug is located at the bottom of the main body; 2) The top cover carries the frame which contains the moving parts of the relay. These comprise the two floats and their associated switches encapsulated in glass bulbs, one calibrated flow valve and two permanent magnets. The cover also carries : • a gas discharge valve(4) with G1/8" in male thread with protective cap. • A valve(5) for pneumatically testing the alarm and insulation circuits, with protective cap. • A push rod(2) for mechanically tripping the alarm and the insulation circuits, with protective cap. A terminal box which as standard contains 4 numbered M6 terminals and one earth terminal. To the external aluminium alloy parts is given a phosphate treatment prior to applying one coat of vinyl enamel, colour 73B03 (light grey GSB). This treatment has proved more than satisfactory over the years for the majority of applications including desert and tropical situations. However, in particularly severe applications (>500h salt fog) such as applications in corrosive atmospheres (acids) a suitable epoxy primer is recommended. (This should be discussed at the time of selection). All external brass fittings are plated and all nuts are made in stainless steel. |